PE gas pipe

Product Details

key word : Seamless Steel Pipe

Product Introduction

PE gas pipe is a new type of pipeline product made from high-density polyethylene special resin and processed by composite extrusion molding process.

| PE Pipe for Gas Supply | ||||

| Nominal outside diameter dn(mm) | Nominal wall thickness(mm) | |||

| PE80 | PE100 | |||

| PN0.3 | PN0.5 | PN0.4 | PN0.7 | |

| SDR17.6 | SDR11 | SDR17.6 | SDR11 | |

| 20 | 2.3 | 3.0 | 2.3 | 3.0 |

| 25 | 2.3 | 3.0 | 2.3 | 3.0 |

| 32 | 2.3 | 3.0 | 2.3 | 3.0 |

| 40 | 2.3 | 3.7 | 2.3 | 3.7 |

| 50 | 2.9 | 4.6 | 2.9 | 4.6 |

| 63 | 3.6 | 5.8 | 3.6 | 5.8 |

| 75 | 4.3 | 6.8 | 4.3 | 6.8 |

| 90 | 5.2 | 8.2 | 5.2 | 8.2 |

| 110 | 6.3 | 10.0 | 6.3 | 10.0 |

| 125 | 7.1 | 11.4 | 7.1 | 11.4 |

| 140 | 8.0 | 12.7 | 8.0 | 12.7 |

| 160 | 9.1 | 14.6 | 9.1 | 14.6 |

| 180 | 10.3 | 16.4 | 10.3 | 16.4 |

| 200 | 11.4 | 18.2 | 11.4 | 18.2 |

| 225 | 12.8 | 20.5 | 12.8 | 20.5 |

| 250 | 14.2 | 22.7 | 14.2 | 22.7 |

| 280 | 15.9 | 25.4 | 15.9 | 25.4 |

| 315 | 17.9 | 28.6 | 17.9 | 28.6 |

| 355 | 20.2 | 32.3 | 20.2 | 32.3 |

| 400 | 22.8 | 36.4 | 22.8 | 36.4 |

| 450 | 25.6 | 40.9 | 25.6 | 40.9 |

| 500 | 28.4 | 45.5 | 28.4 | 45.5 |

| 560 | 31.9 | 50.9 | 31.9 | 50.9 |

| 630 | 35.8 | 57.3 | 35.8 | 57.3 |

| Characteristics | requirements |

| Specific Gravity,g/cm3,(20ºC) | 0.941-0.965 |

| Longitudinal Reversion,%,(110ºC) | ≤3 |

| Oxidation Induction Time,min,(210ºC) | ≥20 |

| Extension Rate at Break,% | ≥350 |

| Melt Mass Flow Rate,g/10min(195ºC,5kg) | Changing of MFR by processing±20% |

| Hydrostatic Stress | |

| Hoop Stres PE100 12.0Mpa,PE8010.0Mpa,100h | No Failure |

| Hoop Stress PE100 5.4Mpa,PE80 4.5Mpa,165h | No Failure |

| Hoop Stress PE100 5.0Mpa,PE80 4.0Mpa,1000h | No Failure |

Product Introduction

1. Non toxic. HDPE material is non-toxic and odorless.

2. Low flow resistance. The inner wall is smooth and the pipeline transportation is convenient. In the same usage environment, the conveying capacity of HDPE pipeline can be increased by 30%, and its roughness is much smaller than that of steel pipe and fiberglass reinforced pipe.

3. No leakage. The connection methods for HDPE pipes include hot melt connection, socket connection, and electric fusion, which means that the strength of the connection point is higher than that of the pipe itself.

4. Strong flexibility. Small diameter high-density polyethylene pipes can be coiled, and large diameter pipes can also be slightly bent, making construction more convenient.

5. Good resistance to flexibility. The wear resistance of HDPE pipes is four times that of steel pipes, which means that HDPE pipes have a longer service life and are more economical and practical.

6. Convenient construction. PE pipes can be installed in various non excavation projects for easy construction and installation.

7. Long lifespan. The practical life at rated temperature and pressure is 50 years.

8. Reduce operating and maintenance costs. High density polyethylene pipes are not only convenient for transportation and installation, but also greatly reduce the labor intensity of workers and improve work efficiency.

Product features

1. The long service life of PE gas pipes can reach 50 years under normal conditions.

2. The strength at the joint will be higher than the strength of the pipeline body when using the electric heating fusion connection method.

3. PE gas pipes can withstand corrosion from various chemical media and have no electrochemical corrosion.

4. The low-temperature embrittlement temperature of PE gas pipes is extremely low, and there will be no brittle cracking phenomenon.

5. PE gas pipes have low notch sensitivity and high shear strength, while also exhibiting excellent resistance to environmental stress cracking.

Product features

1. The long service life of PE gas pipes can reach 50 years under normal conditions.

2. The strength at the joint will be higher than the strength of the pipeline body when using the electric heating fusion connection method.

3. PE gas pipes can withstand corrosion from various chemical media and have no electrochemical corrosion.

4. The low-temperature embrittlement temperature of PE gas pipes is extremely low, and there will be no brittle cracking phenomenon.

5. PE gas pipes have low notch sensitivity and high shear strength, while also exhibiting excellent resistance to environmental stress cracking.

Application scope

Buried polyethylene pipelines for gas use are suitable for gas transmission pipeline systems with operating temperatures ranging from -20 ° C to -40 ° C and long-term high working pressures not exceeding 0.7M PA.

Factory Appearance

Our company has 15 production lines and is capable of continuous production with a monthly inventory of tens of thousands of tons, and a total annual production of tens of millions of tons, ensuring continuous supply to customers.

Packing and shipping

The products are exported to Europe, the United States, South America, Africa, Asia, the Middle East, Australia and other countries and regions. We have our own factories and have established cooperative relations with relevant steel manufacturers to get more technical support, so that our company can perfectly meet the requirements of customers, such as TISCO, Baosteel, Li Steel, Jinsteel, Sinosteel, Jiusteel, Li Steel, Masteel, Wisco, Angang Steel and so on.

Application areas

Products are widely used in tableware, kitchenware, medical equipment, home appliances, auto parts, building decoration, petrochemical and other industries. Our company has extensive experience in the development and export of metal and steel materials. Our company is the long-term reliable steel supplier you are looking for!

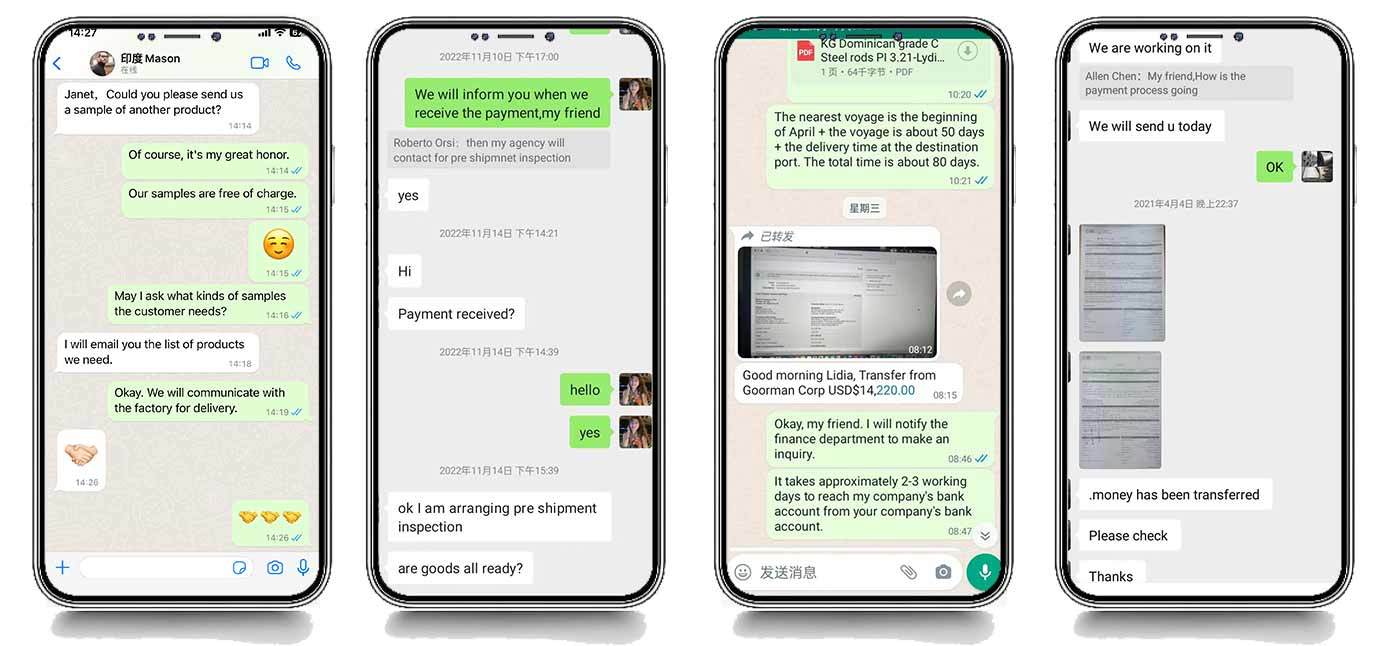

Customer visit

Our company has extensive experience in the development and export of metal and steel materials. Our company is the long-term reliable steel supplier you are looking for!

RELATED PRODUCTS

Get a Free Quote