PE water pipe

Product Details

key word : Seamless Steel Pipe

Introduction to PE pipes

PE pipes have high toughness, but their elongation at break is also relatively high. This makes them more adaptable to uneven extrusion settlement and misalignment, and has good seismic resistance, making the pipeline system stable and reliable.

Due to the smooth wall of the pipe and relatively low resistance, it can make the water flow faster and have a larger flow rate. Compared with other pipes, it has a strong flow capacity. By using fusion welding, the quality of the interface can be ensured, and the integration of the joint and the pipe can be achieved. The strength and bursting strength of the interface are also higher than that of the pipe itself, making it safe and reliable.

Product features

1. Water supply pipes are non-toxic. HDPE material is non-toxic and odorless. It belongs to green building materials and has effectively improved water quality through strict health testing. Ensure that the quality meets your needs.

2. Low flow resistance. The inner wall is smooth and the pipeline transportation is convenient. Under the same conditions, due to its roughness being much smaller than that of steel pipes and fiberglass pipes, the transportation capacity of HDPE pipes can be increased by 30%.

3. No leakage. The connection methods for HDPE pipes include hot melt butt joints, hot melt socket connections, and electric fusion connections, which means that the strength of the connection point is higher than that of the pipe itself.

4. Excellent flexibility. Small diameter high-density polyethylene pipes can be rolled into coils. At the same time, large-diameter products can also have slight bending, making construction sites more convenient.

5. Good scratch resistance. The wear resistance of HDPE pipes is four times that of steel pipes, which means that HDPE pipes have a longer service life and better economy.

6. Convenient construction. PE pipes can be installed in various non excavation methods for easy construction and installation.

7. Long lifespan. Predicted to have a service life of 50 years under rated temperature and pressure design.

8. Reduce operating and maintenance costs. High density polyethylene pipes are not only convenient for transportation and installation, but also greatly reduce the labor intensity of workers and improve work efficiency.

application area

1. Urban water supply system. Large diameter HDPE pipes are healthy and non-toxic, making them more suitable for the use of urban water supply and drainage main and branch pipes.

2. Replace cement pipes, iron pipes, and steel pipes. Suitable for renovation projects, without the need for large-scale excavation, HDPE pipes can be widely used in the renovation of pipeline networks in old urban areas.

3. Industrial raw material transmission pipelines. Industrial raw material conveying pipes for chemical, fiber, food, forestry, pharmaceuticals, light industry, papermaking, metallurgy, and other industries.

4. Landscape water supply network. Due to the need for a large number of water supply pipelines in greening projects, HDPE pipes are the preferred choice for their toughness and low cost.

5. Sewage discharge pipeline. HDPE pipes have unique corrosion resistance and can be used in industrial wastewater and sewage discharge pipelines.

6. Transfer of ore and mud. HDPE pipes have high stress resistance and wear resistance, and can be widely used for transporting ores, coal ash, and river mud.

7. Agricultural irrigation pipelines. HDPE pipes have the advantages of high flow rate and good impact resistance, making them ideal tools for agricultural irrigation.

| National standard nominal wall thickness of water supply pipe | ||||||||

| GB/T 13663.2-2018 | Nominal Size | |||||||

| SDR41 | SDR33 | SDR26 | SDR21 | SDR17 | SDR13.6 | SDR11 | SDR9 | |

| PE80 Nominal Press (Mpa) | ||||||||

| 0.32 | 0.4 | 0.5 | 0.6 | 0.8 | 1 | 1.25 | 1.6 | |

| PE100 Nominal Press (Mpa) | ||||||||

| 0.4 | 0.5 | 0.6 | 0.8 | 1 | 1.25 | 1.6 | 2 | |

| DN(mm) | TK(mm) | TK(mm) | TK(mm) | TK(mm) | TK(mm) | TK(mm) | TK(mm) | TK(mm) |

| 16 | 2.3 | |||||||

| 20 | 2.3 | 2.3 | ||||||

| 25 | 2.3 | 2.3 | 3 | |||||

| 32 | 2.3 | 2.4 | 3 | 3.6 | ||||

| 40 | 2.3 | 2.4 | 3 | 3.7 | 4.5 | |||

| 50 | 2.3 | 2.4 | 3 | 3.7 | 4.6 | 5.6 | ||

| 63 | 2.5 | 3 | 3.8 | 4.7 | 5.8 | 7.1 | ||

| 75 | 2.9 | 3.6 | 4.5 | 5.6 | 6.8 | 8.4 | ||

| 90 | 3.5 | 4.3 | 5.4 | 6.7 | 8.2 | 10.1 | ||

| 110 | 4.2 | 5.3 | 6.6 | 8.1 | 10 | 12.3 | ||

| 125 | 4.8 | 6 | 7.4 | 9.2 | 11.4 | 14 | ||

| 140 | 5.4 | 6.7 | 8.3 | 10.3 | 12.7 | 15.7 | ||

| 160 | 6.2 | 7.7 | 9.5 | 11.8 | 14.6 | 17.9 | ||

| 180 | 6.9 | 8.6 | 10.7 | 13.3 | 16.4 | 20.1 | ||

| 200 | 7.7 | 9.6 | 11.9 | 14.7 | 18.2 | 22.4 | ||

| 225 | 8.6 | 10.8 | 13.4 | 16.6 | 20.5 | 25.2 | ||

| 250 | 9.6 | 11.9 | 14.8 | 18.4 | 22.7 | 27.9 | ||

| 280 | 10.7 | 13.4 | 16.6 | 20.6 | 25.4 | 31.3 | ||

| 315 | 7.7 | 9.7 | 12.1 | 15 | 18.7 | 23.2 | 28.6 | 35.2 |

| 355 | 8.7 | 10.9 | 13.6 | 16.9 | 21.1 | 26.1 | 32.2 | 39.7 |

| 400 | 9.8 | 12.3 | 15.3 | 19.1 | 23.7 | 29.4 | 36.3 | 44.7 |

| 450 | 11 | 13.8 | 17.2 | 21.5 | 26.7 | 33.1 | 40.9 | 50.3 |

| 500 | 12.3 | 15.3 | 19.1 | 23.9 | 29.7 | 36.8 | 45.4 | 55.8 |

| 560 | 13.7 | 17.2 | 21.4 | 26.7 | 33.2 | 41.2 | 50.8 | 62.5 |

| 630 | 15.4 | 19.3 | 24.1 | 30 | 37.4 | 46.3 | 57.2 | 70.3 |

| 710 | 17.4 | 21.8 | 27.2 | 33.9 | 42.1 | 52.2 | 64.5 | 79.3 |

| 800 | 19.6 | 24.5 | 30.6 | 38.1 | 47.4 | 58.8 | 72.6 | 89.3 |

| 900 | 22 | 27.6 | 34.4 | 42.9 | 53.3 | 66.2 | 81.7 | |

| 1000 | 24.5 | 30.6 | 38.2 | 47.7 | 59.3 | 72.5 | 90.2 | |

| 1200 | 29.4 | 36.7 | 45.9 | 57.2 | 67.9 | 88.2 | ||

| 1400 | 34.3 | 42.9 | 53.5 | 66.7 | 82.4 | 102.9 | ||

| 1600 | 39.2 | 49 | 61.2 | 76.2 | 94.1 | 117.6 | ||

| 1800 | 43.8 | 54.5 | 69.1 | 85.7 | 105.9 | |||

| 2000 | 48.8 | 60.6 | 76.9 | 95.2 | 117.6 | |||

| 2250 | 55 | 70 | 86 | 107.2 | ||||

| 2500 | 61.2 | 77.7 | 95.6 | 119.1 | ||||

Factory Appearance

Our company has 15 production lines and is capable of continuous production with a monthly inventory of tens of thousands of tons, and a total annual production of tens of millions of tons, ensuring continuous supply to customers.

Packing and shipping

The products are exported to Europe, the United States, South America, Africa, Asia, the Middle East, Australia and other countries and regions. We have our own factories and have established cooperative relations with relevant steel manufacturers to get more technical support, so that our company can perfectly meet the requirements of customers, such as TISCO, Baosteel, Li Steel, Jinsteel, Sinosteel, Jiusteel, Li Steel, Masteel, Wisco, Angang Steel and so on.

Application areas

Products are widely used in tableware, kitchenware, medical equipment, home appliances, auto parts, building decoration, petrochemical and other industries. Our company has extensive experience in the development and export of metal and steel materials. Our company is the long-term reliable steel supplier you are looking for!

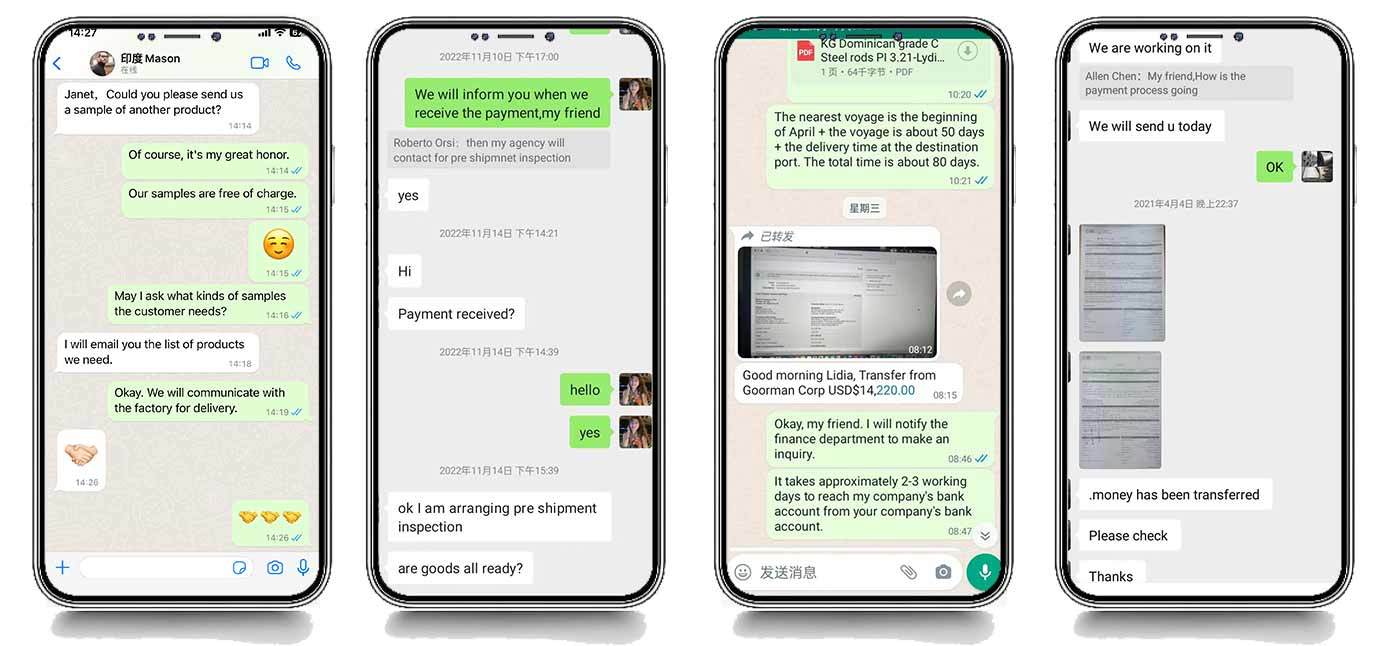

Customer visit

Our company has extensive experience in the development and export of metal and steel materials. Our company is the long-term reliable steel supplier you are looking for!

RELATED PRODUCTS

Get a Free Quote