Ductile iron pipe

Product Details

key word : Seamless Steel Pipe

With its high strength, high elongation, corrosion resistance, resistance to shock, easy construction and many other fine features, ductile iron pipe is the best choice in today's world for conveying water and gas safely. Ductile iron, also called nodular iron or spheroidal graphite iron, is characterized by the presence of spheroidal graphite in the resultant castings.

Ductile iron pipes are available in a range of diameters from 80mm to 1600mm and are suitable for both potable water transmission and distribution (in accordance with BS EN 545) and sewerage (in accordance with BS EN 598).

Ductile iron pipes are simple to joint, can be laid in all weather conditions and often without the need for selected backfill. Its high safety factor and ability to accommodate ground movement make it the ideal pipeline material for a wide range of applications.

Ductile iron pipe is made of magnesium or rare earth magnesium combined with gold nodularizing agent added to molten iron before pouring to make graphite spheroidized and reduce stress concentration, so that the pipe has high strength, high elongation, impact resistance, corrosion resistance, good sealing, etc. Advantages of pipe fittings; the inner wall is lined with cement mortar, which improves the water delivery environment of the pipeline, improves the water supply capacity, and reduces energy consumption; the nozzle adopts a flexible interface, and the pipe itself has a large elongation rate, which makes the pipe more flexible. In the buried pipeline, it can work together with the soil around the pipeline to improve the stress state of the pipeline, thereby improving the reliability of the pipeline network operation.

Ductile iron pipe is mainly called centrifugal ductile iron pipe. It has the essence of iron and the performance of steel, excellent anti-corrosion performance, good ductility, good sealing effect, easy installation, and is mainly used for water supply, gas transmission, and transportation in municipal and industrial and mining enterprises. oil etc. It is the first choice for water supply pipes with high cost performance. Compared with PE pipes, ductile ink tubes are simpler and quicker to install than PE pipes in terms of installation time, and the internal and external bearing pressure is better after installation; from the perspective of airtightness and corrosion resistance, ductile ink pipes are better airtight after installation, and also Various anti-corrosion methods can be used to improve the anti-corrosion performance; from the perspective of hydraulic performance, the specification of ductile ink tube generally refers to the inner diameter, and the specification of PE pipe generally refers to the outer diameter, because under the same specification conditions, the ductile ink tube can achieve greater runoff flow; from In terms of comprehensive installation and maintenance costs, the ductile ink tube has a more superior cost performance. The inner wall is sprayed with zinc, cement mortar anti-corrosion materials, etc.

|

Material |

Ductile Cast Iron |

|

Type |

T-Type(push-on joint) |

|

K-Type |

|

|

Self-Restrained |

|

|

Standard |

ISO2531, EN545, EN598 etc |

|

Size |

DN80- DN2600 |

|

Classs |

K7, K8, K9, C40, C30, C25, etc |

|

Length |

6m, cut to 5.7m |

|

Internal Coating |

1. Portland cement mortar lining |

|

2. Sulphate Resistant cement mortar lining |

|

|

3. High-Aluminum cement mortar lining |

|

|

4. Epoxy Resin Lining |

|

|

5. Epoxy Ceramic Lining |

|

|

External Coating |

Zinc+bitumen(70microns) painting |

|

Rubber Gasket |

NBR rubber, SBR rubber or EPDM rubber ring as per ISO4633 |

|

Application |

Potable Water / Drinking Water |

|

Sewage Water |

|

|

Packing |

DN100-DN300 in bundles; DN350-DN2600 in bulk ship |

|

Note |

The pipe coating can be customized, such as, zinc-aluminum alloy, PU, etc. |

Factory Appearance

Our company has 15 production lines and is capable of continuous production with a monthly inventory of tens of thousands of tons, and a total annual production of tens of millions of tons, ensuring continuous supply to customers.

Packing and shipping

The products are exported to Europe, the United States, South America, Africa, Asia, the Middle East, Australia and other countries and regions. We have our own factories and have established cooperative relations with relevant steel manufacturers to get more technical support, so that our company can perfectly meet the requirements of customers, such as TISCO, Baosteel, Li Steel, Jinsteel, Sinosteel, Jiusteel, Li Steel, Masteel, Wisco, Angang Steel and so on.

Application areas

Products are widely used in tableware, kitchenware, medical equipment, home appliances, auto parts, building decoration, petrochemical and other industries. Our company has extensive experience in the development and export of metal and steel materials. Our company is the long-term reliable steel supplier you are looking for!

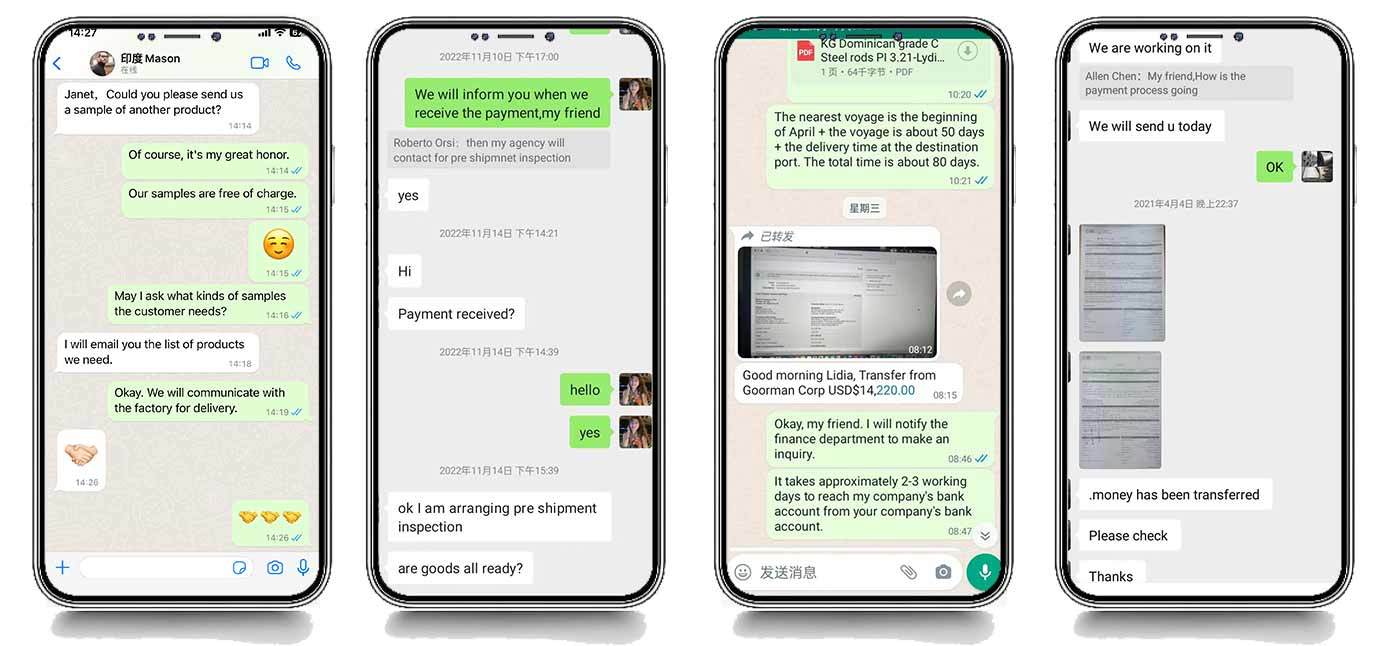

Customer visit

Our company has extensive experience in the development and export of metal and steel materials. Our company is the long-term reliable steel supplier you are looking for!

RELATED PRODUCTS

Get a Free Quote